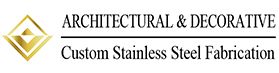

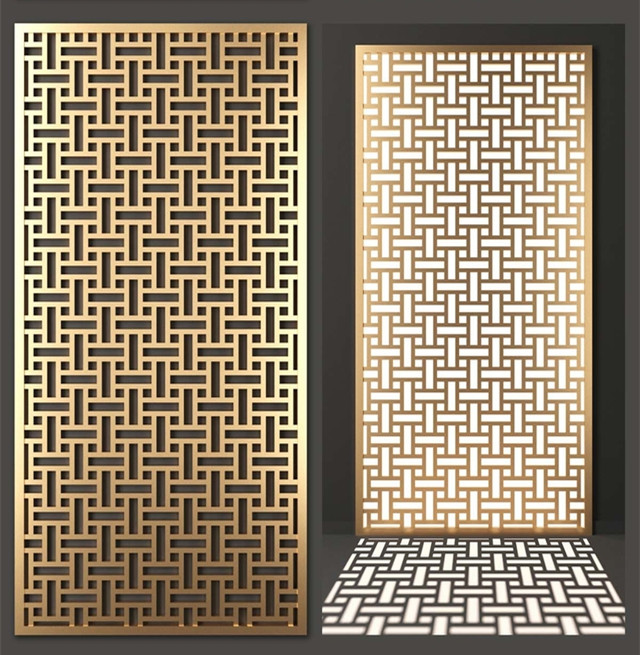

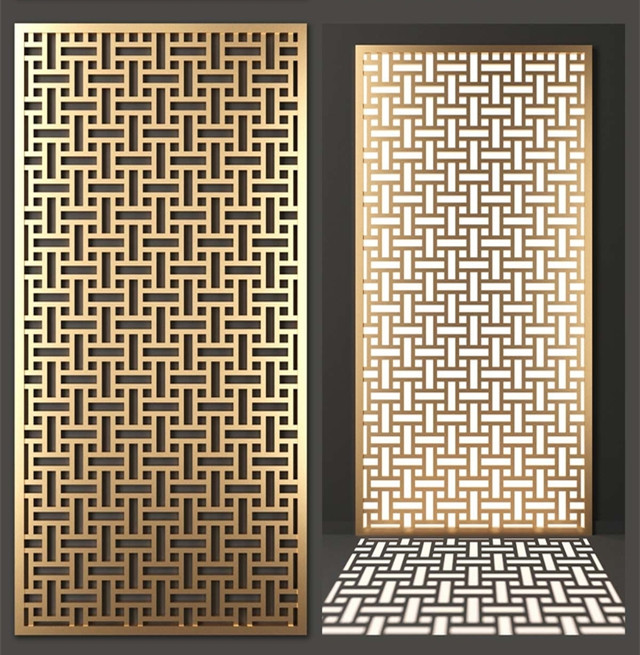

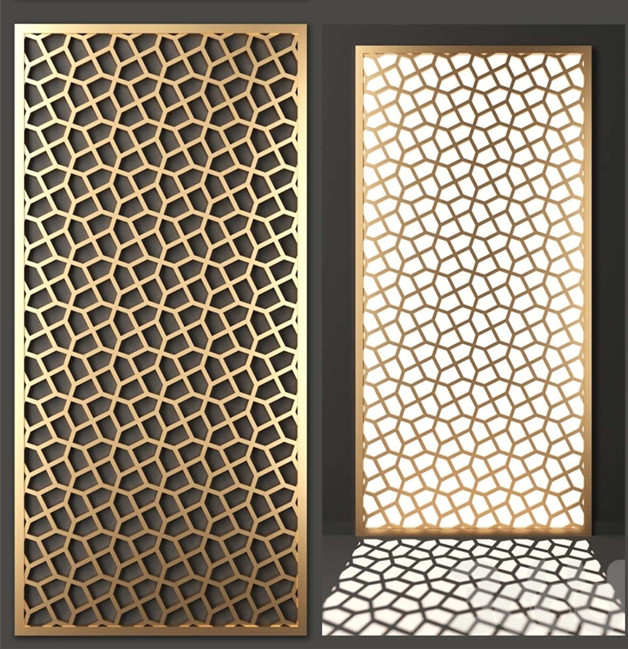

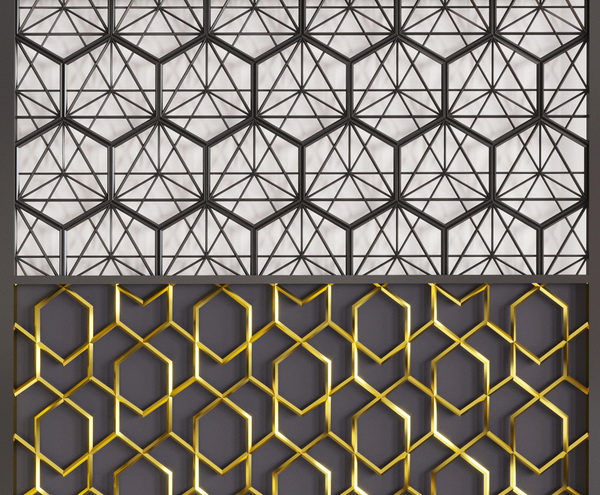

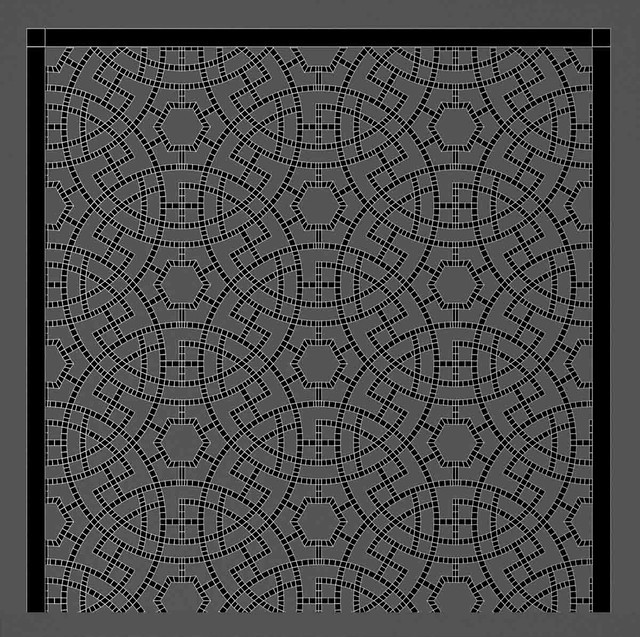

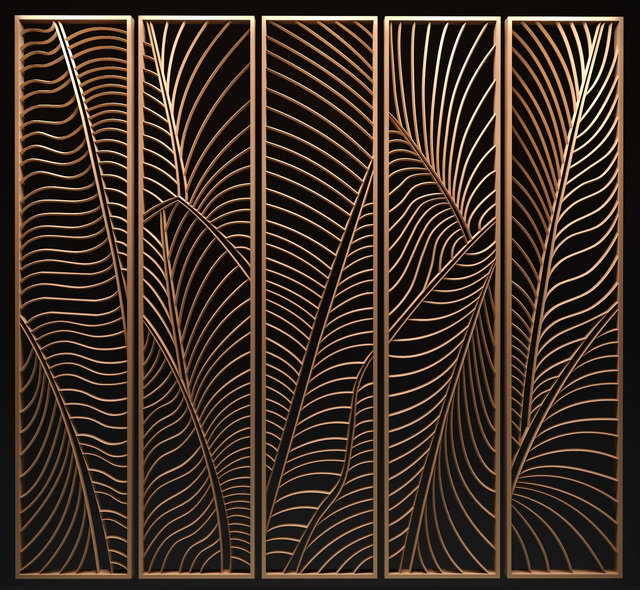

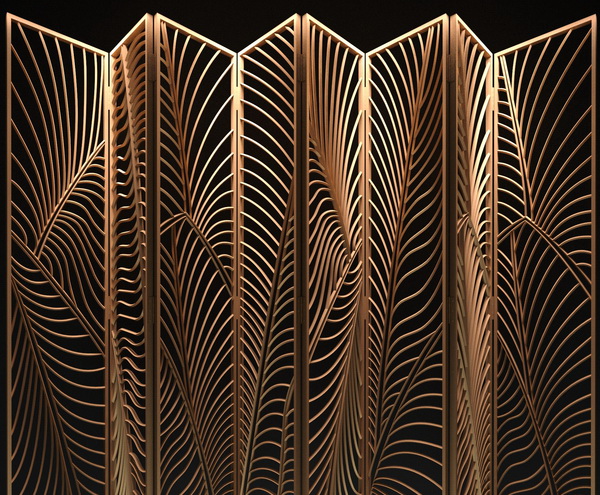

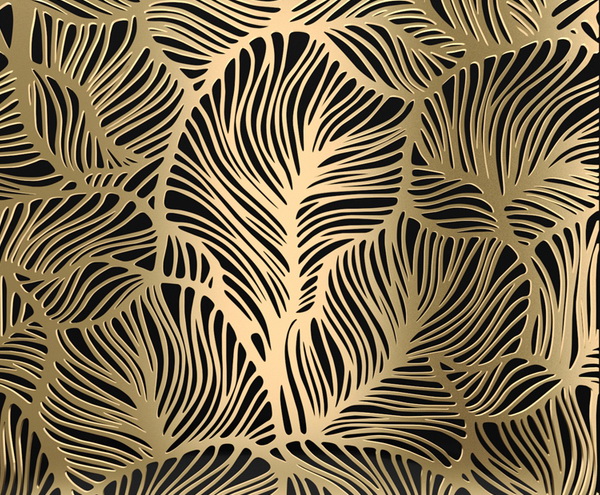

Stainless Steel Laser Cut Screen Design

Stainless Steel Laser Cut Screen Design

Type:Screens & Room Dividers

Place of Origin:Guangdong, China (Mainland)

Brand Name:Mirror Metal

Model Number:Stainless Steel Laser Cut Screen Design

Material:Metal

Metal Type:Stainless Steel / Alumimum

Color: Hotel Gold, Rosegold, Champagne Gold, Black, and Customized

Usage:Hotel

Application:Partitions Application

Product Name: stainless steel laser cut screen design

Size:Customized Size

Feature:Eco-friendly

Style:European-style

Package:Wooden Case

Certificate:ISO

Place of Origin:Guangdong, China (Mainland)

Brand Name:Mirror Metal

Model Number:Stainless Steel Laser Cut Screen Design

Material:Metal

Metal Type:Stainless Steel / Alumimum

Color: Hotel Gold, Rosegold, Champagne Gold, Black, and Customized

Usage:Hotel

Application:Partitions Application

Product Name: stainless steel laser cut screen design

Size:Customized Size

Feature:Eco-friendly

Style:European-style

Package:Wooden Case

Certificate:ISO

Stainless Steel Laser Cut Screen Design

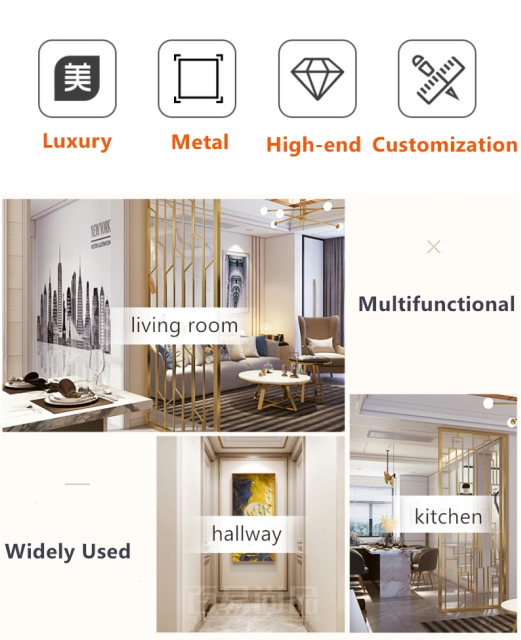

The stainless steel laser cut screen design are more and more popular in modern interior design.

Compared with other material of partitions, the stainless steel screens have unique corrosion resistance and high temperature resistance, which are more suitable for modern style decoration, including hotels, bars, restaurants, leisure, offices, financial institutions as well as luxury residences and apartments.

| Name | Stainless steel laser cut screen panel |

| Size | Customized |

| Color | Silver/Gold/Customized |

| Surface finish | Hairline/Mirror/Customized |

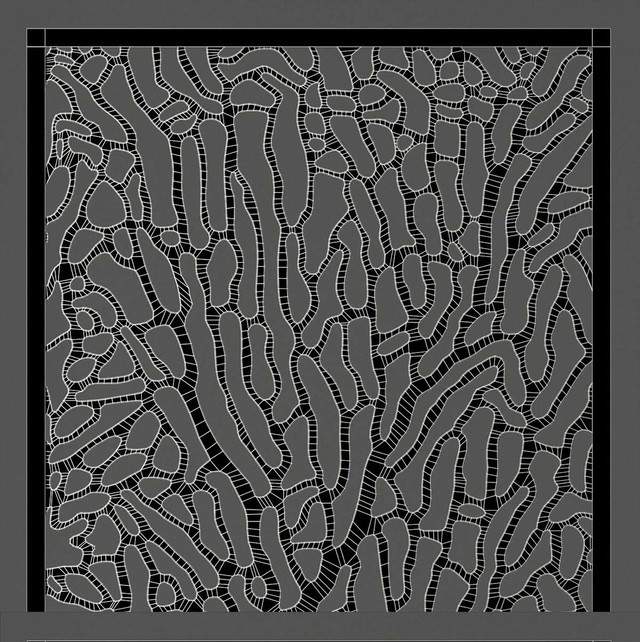

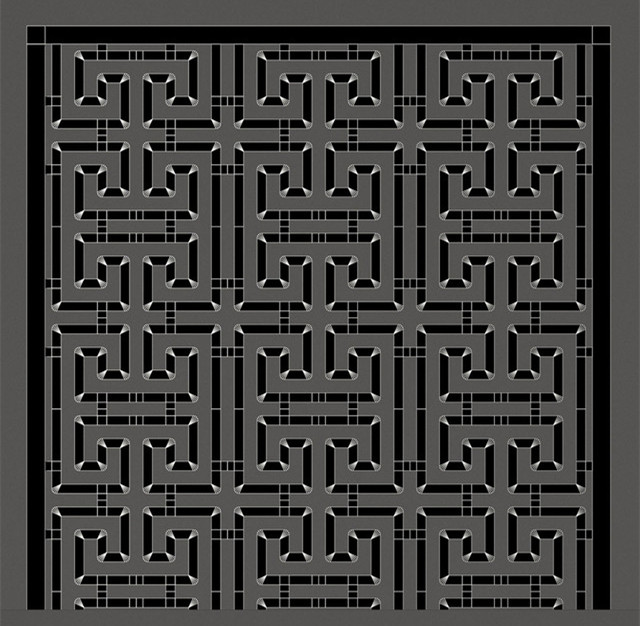

| Design/pattern | Customized |

| Processing technics | Cutting, welding, bending, polishing and PVD coating |

| Material | High quality 304 or 316 stainless steel |

| Quality standard | 1.Hairline or 8k high polishing degree (or as per customers’ requirements) 2. The material used strictly accords to international standard 3. Precision argon arc welding technique 4. Professional QC team |

- Customer sends picture or CAD design to us, we make detailed drawing/ 3D mold and show to clients for confirmation.

- Making exact screen according to the CAD design .

- Cutting//Bending/Welding/PVD/Polishing as needed.

- Take different views pictures/ videos and show to clients.

We handle in a careful and economic way for ocean shipping, like paper box,pallet,or carton.

Package size and container loading quantity are calculated by engineers based on products size in order

to work out a best solution.

Every piece is fixed by protective foam, plastic tape, batten etc. to protect products from shipping damage.

To conclude:

1. Custom plywood crate or box for heavy sheet metal parts.

2. Heavy duty carton for small and lighter metal parts.

3. Bubble bag or protective film for inner protection to avoid scratches.

4. Plywood pallet is available when sheet metal products are in large amount.

5. Shipping marks as per request

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.